McNICHOLS® Bar Grating Resources

McNICHOLS® Bar Grating brings safety, strength, durability, and character when installed in either industrial or architectural applications. It regularly appears on catwalks, factory floors, platforms, railing infill panels, and as Stair Treads. A series of bearing bars are welded, swage-locked, or press-locked with perpendicular crossbars to form the panels.

Bar Grating is a rugged, high-performance, low-maintenance, and slip-resistant product capable of handling pedestrian or vehicular loads. McNICHOLS also has a complete line of Bar Grating Stair Treads and available resources. For information on Bar Grating Stair Treads, please visit our Stair Tread Resources landing page.

Benefits of Bar Grating

- Safety and slip-resistance

- High strength-to-weight ratio

- Load-bearing capability

- Ease of fabrication

- Variety of materials, panel configurations and sizes

- Ventilation of air, light, liquid and sound

- Range of open areas for filtration

- Product longevity

- Low Maintenance

- ADA-compliant choices

How to Specify and Order Bar Grating

The outline below will help you specify the right McNICHOLS® Bar Grating product for your next project. Providing these details ensures accuracy in design, quoting, and fulfillment.

Application

Before selecting a product, consider how the Bar Grating will be used. Load requirements, span, and support spacing are key factors, along with expected traffic—such as pedestrian, handcart, or vehicle use. Some McNICHOLS® Bar Grating options meet ADA (Americans with Disabilities Act) standards when installed properly. Explore our Product and Application Gallery for examples of Bar Grating in use across industries.

Construction Type

Secondly, choose from several construction styles, including Standard-Duty Welded, Heavy-Duty Welded, Swage-Locked, Press-Locked, and Clinched. Each construction offers unique performance and aesthetic characteristics suited to specific environments. Learn more in the construction types section of this page.

Series Type & Name

Select the appropriate series designation, such as GW-100, GHB-150, or GAL-125. Items that meet ADA spacing requirements will note this compliance within the product description and specifications.

Product Spacing

Determine your required bar spacing, which is the distance from the center of one bearing bar to the next. Common designations such as 19-W-4 indicate:

19 = 1-3/16" bearing bar spacing

W = welded construction type

4 = 4" crossbar spacing

Selecting the correct spacing ensures the proper balance of strength, open area, and function for your installation.

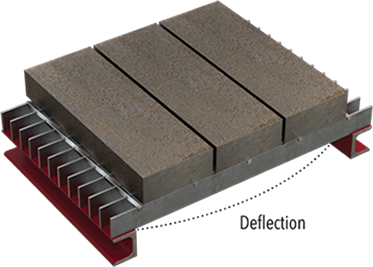

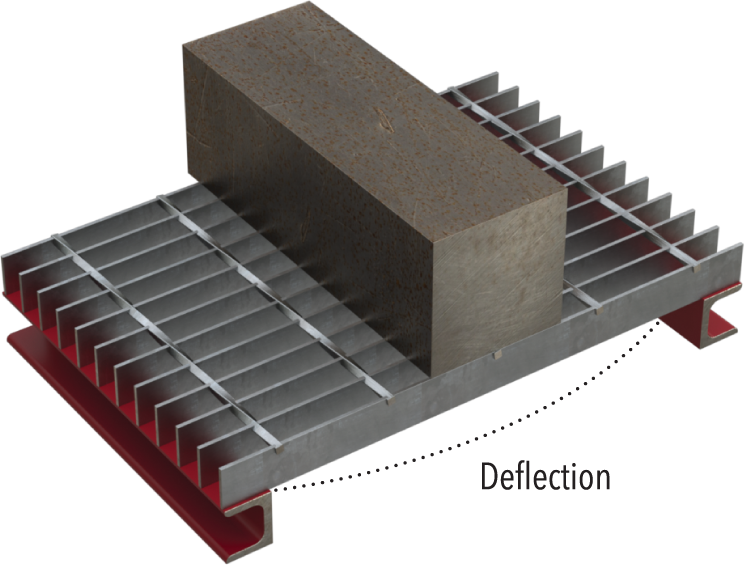

Loading and Span: the bearing bar direction must be installed parallel to the span (Length) to adequately support the application load. Clear span, which refers to the distance between Bar Grating supports, is a critical factor in installation. Load Tables include sperate values for Uniform Load (denoted by "U") and Concentrated Load (denoted by "C"), allowing you to consider the type of load being applied.

It is essential to consider weight distribution and deflection—whether stationary, evenly distributed, or light pedestrian traffic—as each affects performance and longevity. If unsure about installation or application, consult an engineer for safety and suitability.

Primary Material & FInish

McNICHOLS® Bar Grating is available in Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel. Standard finish options include mill finish, Hot-Dipped Galvanized, or Powder Coated (black or gray) for select items.

Alloy, Grade, or Type

Depending on your environment, a specific material alloy or grade may offer better corrosion resistance, temperature performance, or strength characteristics. Consider these factors early in your selection process.

Bearing Bar Size & Shape

Bearing bars define the load-bearing capacity of your grating. Choose from Rectangular Bar, I-Bar, or T-Bar shapes, available in a range of heights and thicknesses, such as 1-1/4" height x 3/16" thick.

Product Surface

Then, select a surface texture suited to your application. Options include smooth, serrated, or grooved surfaces—each designed to provide the right level of traction and slip resistance.

Percent Open Area

Review the percentage of open area to ensure proper drainage, airflow, or visibility as required by your design.

Span

Determine the bearing bar direction to align with the load-bearing supports. Clear span refers to the distance between these supports, an essential factor for ensuring safe installation and proper load distribution.

Product Size, Form, & Quantity

Next, specify panel dimensions, cut-to-size sections, stair treads, or other fabricated pieces. Note whether panels should be uniform, random, or equal stub cut. Larger widths may be supplied in multiple sections.

Special Requirements

If your project involves fabrication, banding, notching, cutouts, toe plates, or non-standard tolerances, please include those details in your specifications.

Accessories

To complete your installation, consider Bar Grating Accessories such as clips, fasteners, carrier plates, and other hardware designed for secure attachment and long-term performance.

How to Specify and Order Bar Grating Stair Treads

Use the guide below to help you specify the correct McNICHOLS® Bar Grating Stair Treads for your project. Providing the right details will ensure safe, durable, and precise installation results.

Application

To start off, consider performance factors such as load capacity, slip resistance, environment, and frequency of use. These stair components are ideal for industrial, commercial, and architectural applications that demand strength and drainage.

Construction Type

McNICHOLS® Stair Treads are available in several construction types, including Standard-Duty Welded, Heavy-Duty Welded, Swage-Locked, and Press-Locked. Each option offers a unique combination of strength, appearance, and cost efficiency based on your project’s requirements.

Series Type & Name

Then, choose the appropriate series type and name, such as GW-100, GHB-150, or GAL-125, to match your structural and aesthetic needs. Series identification ensures consistent specifications with McNICHOLS® Bar Grating panels for seamless integration across stairways and platforms.

Product Spacing

Next, determine your desired bearing bar spacing, the distance from the center of one bearing bar to the next. Industry-standard spacing designations such as 19-W-4 indicate key product details:

- 19 = 1-3/16" bearing bar spacing

- W = welded construction

- 4 = 4" crossbar spacing

Selecting the correct spacing ensures proper strength, open area, and code compliance for pedestrian safety.

Primary Material & FInish

McNICHOLS® Bar Grating Stair Treads are offered in Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel. Finishes vary by material, including Mill Finish, Hot-Dipped Galvanized, and Powder Coated (Black or Gray). Choose a finish that complements your environment and enhances corrosion protection.

Alloy, Grade, or Type

Depending on environmental exposure or load demands, select a specific alloy, grade, or type to optimize corrosion resistance, strength, or temperature tolerance. This ensures long-term performance and compliance with safety standards.

Depending on environmental exposure or load demands, select a specific alloy, grade, or type to optimize corrosion resistance, strength, or temperature tolerance. This ensures long-term performance and compliance with safety standards.

Bearing Bar Size & Shape

Afterwards, select the height and thickness of the bearing bars (e.g., 1-1/4" Height x 3/16" Thick) as well as the bar shape—Rectangular, I-Bar, or T-Bar—to achieve the required load-bearing capacity and design style.

Product Surface

Choose the surface texture that best meets your safety needs: Smooth, Serrated, or Grooved. Serrated surfaces provide additional traction and are recommended for outdoor or wet environments.

Percent Open Area

Then, review the percentage of open area to ensure the right balance between drainage, airflow, and solid footing.

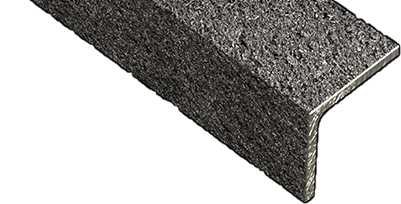

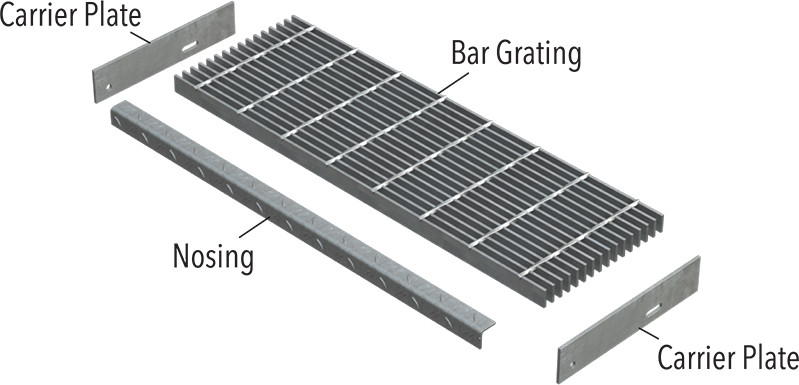

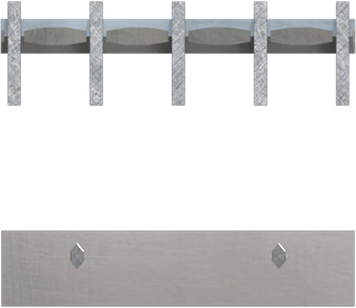

Nosing

Each Bar Grating Stair Tread typically includes a 90° Angle Nosing welded to the leading edge for enhanced visibility, slip resistance, and durability.

A common option is the Checkered Plate Nosing, the most popular choice for heavy-duty and industrial environments. All standard inventory treads are supplied with Nosing installed for quick installation.

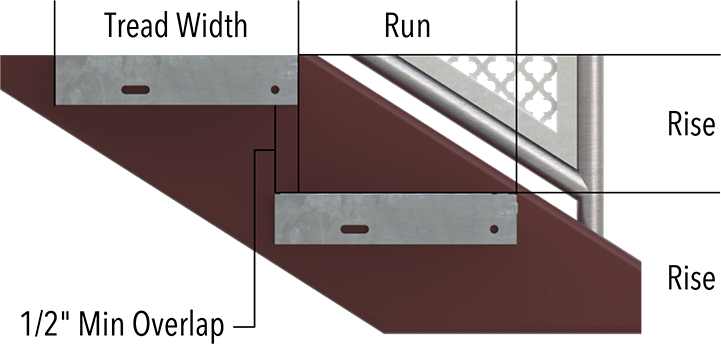

Carrier Plates

Carrier Plates (End Plates) are welded to each end of the Stair Tread to provide mounting strength and stability. Each plate includes a bolt hole and mounting slot for easy attachment to structural supports.

Standard Carrier Plates are typically 3/16" thick and securely welded to both the bearing bars and Nosing. For convenience, prefabricated inventory treads come with Carrier Plates.

Product Size, Form, & Quantity

Specify the width, length (span), and quantity of treads needed. The width is measured from the front edge of the Nosing to the back edge of the last bearing bar, while the length (span) extends between the outside edges of the Carrier Plates.

Then, indicate any cut-to-size or fabrication requirements at the time of order.

Special Requirements

Bar Grating Construction Types

McNICHOLS offers five different construction types of Bar Grating: Standard-Duty Welded, Heavy-Duty Welded, Swage-Locked, Press-Locked, and Clinched. Most construction types can be cut down and fabricated into Bar Grating Stair Treads and other platform or landing sizes.

The construction of Bar Grating, regardless of the type, is a manufacturing process that adjoins a number of parallel bearing bars with perpendicular crossbars. To do this, crossbars are either welded to the bearing bars, inserted into pre-punched bearing bars, or pressed and locked into a series of parallel bearing bars. Additionally, Bar Grating can be clinched together to form a hexagonal grid.

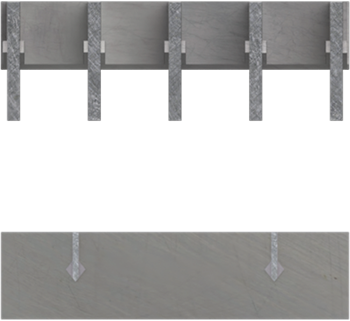

Welded

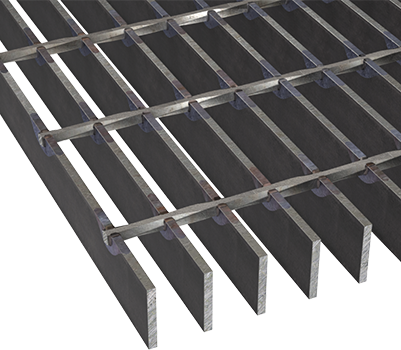

A trusted solution for industrial, architectural, and infrastructure applications, McNICHOLS® Welded Bar Grating ensures strength, safety, and durability. Each panel features rectangular-shaped bearing bars joined to 1/4" square or twisted crossbars using an electro-forge welding process. This method combines intense hydraulic pressure with high electrical current, fusing the bars together into a rigid, load-bearing structure capable of withstanding demanding conditions.

Available in a wide range of materials, bar thicknesses, heights, and spacings, Welded Bar Grating is a top choice for walkways, platforms, mezzanines, trenches, and flooring systems. Its clean, open design allows for superior load distribution, drainage, and air circulation, all while delivering the long-term cost efficiency and strength-to-weight ratio McNICHOLS products are known for.

For general-purpose pedestrian and light-duty wheel traffic, McNICHOLS offers multiple welded grating series tailored to your project’s load requirements.

Each Welded Bar Grating panel is manufactured using precision spacing between bearing bars, ensuring consistency and strength across every piece. Standard crossbar spacing is 4" on center, with an optional 2" spacing available for tighter surface designs.

Heavy-Duty Welded

When your project calls for maximum load-bearing capability, McNICHOLS® Heavy-Duty Welded Bar Grating delivers. Constructed using the same electro-forge process as standard welded grating, these panels are built with larger bearing bars and crossbars to handle high wheel loads and extreme conditions.

Ideal for bridge decks, highways, airport runways, loading docks, and heavy trench covers, McNICHOLS GHB Series Grating offers bearing bar thicknesses up to 1/4" and bar heights ranging from 1" to 3". This makes it capable of supporting truck, forklift, and aircraft traffic while maintaining superior traction and drainage.

Upon request, custom configurations, finishes, and material options—including Carbon Steel, Stainless Steel, and Aluminum—are also available.

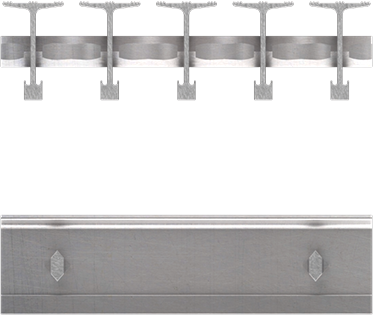

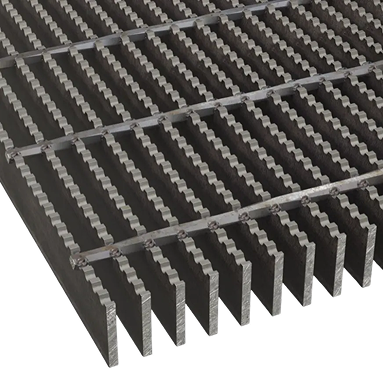

Swage-Locked

Delivering a balance of high-strength rigidity and lightweight performance, McNICHOLS® Swage-Locked Bar Grating is an ideal solution for demanding environments. Constructed from Aluminum for superior corrosion resistance, this virtually maintenance-free grating solution is ideal for applications where durability and reduced weight are key.

Each Swage-Locked panel is available in multiple construction types, Rectangular Bar, I-Bar, and T-Bar with various bar heights, thicknesses, and spacings to suit your specific design and load requirements.

The defining feature of McNICHOLS® Swage-Locked Grating is its precision mechanical locking system. During manufacturing, square crossbars are inserted into pre-punched holes within the bearing bars. A hydraulic swaging process then reshapes these crossbars, locking them securely in place under extreme pressure.

In most Swage-Locked Grating types, the crossbar intersection sits midway along the bearing bar height. However, in our SFT Series, the crossbar is flush with the top surface, creating a smooth, uniform appearance that’s both functional and visually appealing.

McNICHOLS offers several series of Swage-Locked Bar Grating to meet design, aesthetic, and performance needs.

Aluminum Swage-Locked Grating with rectangular-shaped bearing bars. Known for its balance of strength, weight, and open area.

Constructed with I-Bar shaped bearing bars that increase surface area for improved load distribution and walking comfort, while the narrow center reduces weight.

GAL Series Grating with a flushed top creates a flat, uniform surface ideal for architectural use and clean aesthetics (SFT, SFT-2).

An exclusive McNICHOLS® ADA-compliant T-Bar design, engineered for slip resistance and pedestrian safety. SAFE-T-GRID® meets ADA requirements for Grating opening size and surface smoothness without compromising function.

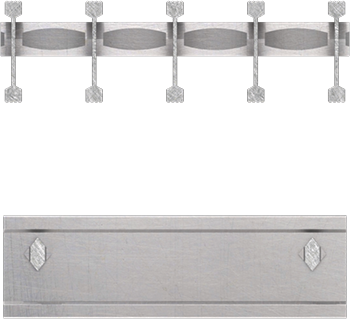

Press-Locked

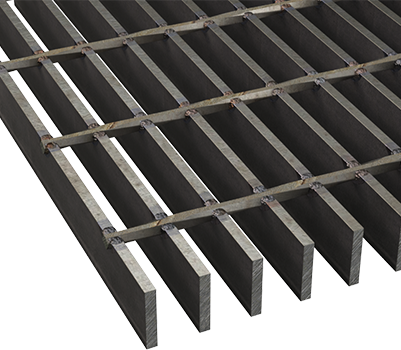

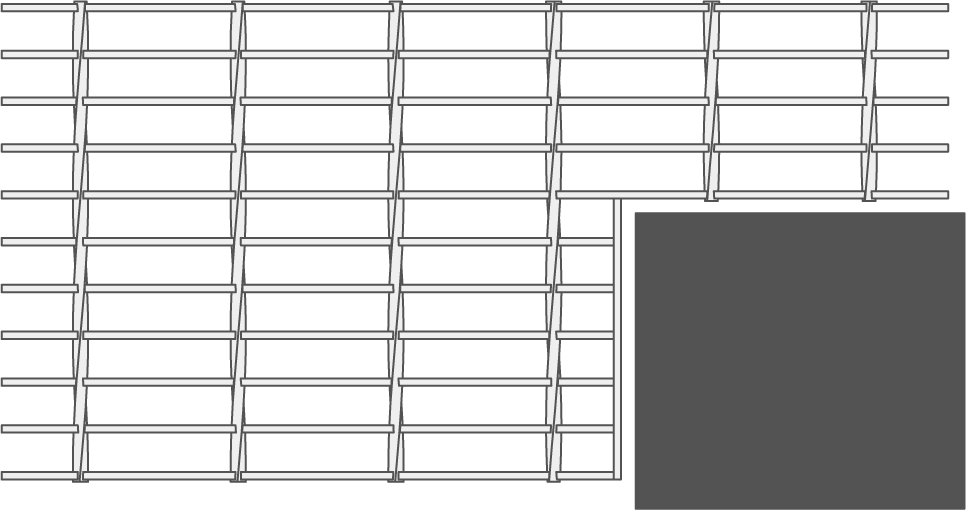

McNICHOLS® Press-Locked Bar Grating combines clean aesthetics with exceptional strength and precision. Designed for both functional and architectural applications, this grating type features a bi-directional flush surface that ensures a firm, rigid construction while maintaining a streamlined, modern appearance.

Press-Locked Grating is manufactured using a high-pressure mechanical process that notches and presses crossbars and bearing bars together, locking them in place without the need for welding. The result is a durable, flat-top surface that provides excellent load distribution, dimensional consistency, and visual appeal across a wide range of environments.

The Press-Locked manufacturing process relies on tremendous hydraulic pressure to interlock the rectangular bearing bars and crossbars. During assembly, the crossbars are pressed into notches in the bearing bars under extreme force, creating a permanent, mechanically locked joint.

Thus, this technique produces a flush-top, rigid grating panel with superior lateral support and minimal open area—characteristics that enhance both safety and appearance.

- Bearing Bars run parallel to the panel's length and carry the primary load-bearing responsibility.

- Crossbars run perpendicular, helping to hold the bearing bars in place while also contributing to the panel's overall stiffness and deflection performance.

Because of its construction, Press-Locked Grating offers a smooth walking surface that’s easy to clean and visually consistent, making it popular for architectural applications, public spaces, and industrial flooring systems that require a polished finish.

McNICHOLS offers two distinct series within the Press-Locked Bar Grating family:

- GCM (CLOSE MESH) Series: Engineered with tighter bearing bar spacing for ADA compliance, GCM Grating provides a safer walking surface and meets requirements for pedestrian accessibility. CLOSE MESH construction delivers a sleek, uniform look while maintaining excellent structural performance.

- GAA Series: Designed as a Welded or Swage-Locked alternative, the GAA Series pairs seamlessly with other Rectangular Bar Grating products such as the GW or GAL Series, making it a versatile choice for mixed-use installations or retrofit projects.

Clinched (HEXMESH™)

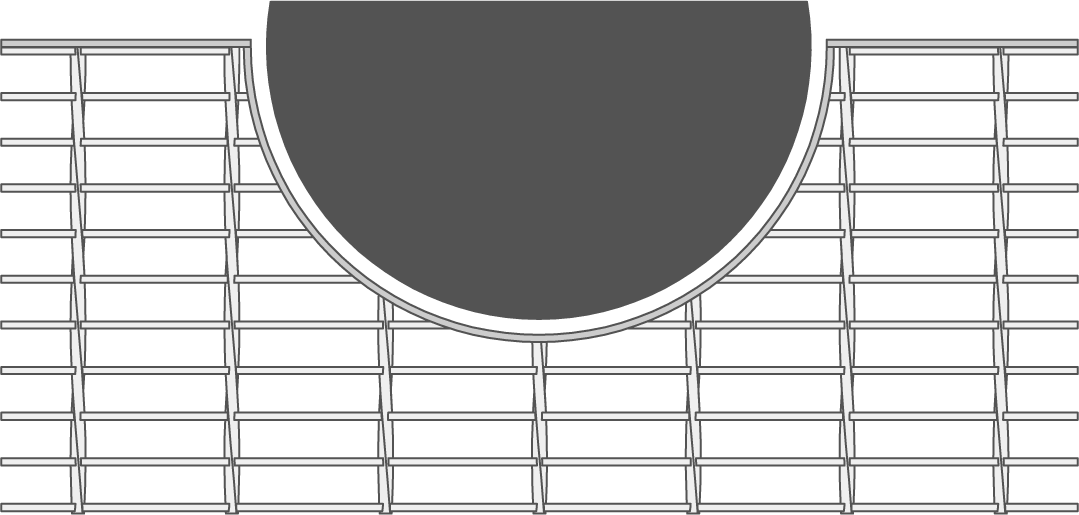

McNICHOLS® HEXMESH™ Clinched Grating is an engineered reinforcement solution designed to withstand the world’s most demanding industrial environments. Categorized as Clinched Grating, HEXMESH™ features a unique hexagonal grid pattern of interlocking "shells" that act as castable anchors for mechanical strength, corrosion resistance, and dimensional stability.

In flooring applications, Clinched Grating serves as a protective armor layer that strengthens and stabilizes concrete in high-impact areas. It is especially beneficial for:

- Loading docks, ramps, and industrial aisles subject to forklift and vehicle traffic

- Foundries, forge shops, and steel mills where floors endure thermal stress and molten material exposure

- Refuse and recycling plants, manufacturing facilities, and heavy-duty work zones requiring resistance to abrasion, shock, and vibration

Available in Carbon Steel and Stainless Steel, McNICHOLS® HEXMESH™ Clinched Grating provides flexibility to meet various environmental and performance demands.

- Construction Type: Clinched (tight or loose clinch options available)

- Available Heights (Depths): 3/4", 1", and 1-1/4"

- Panel Dimensions: Standard 36" width × 120" length

Optional Features: Available with or without lanced openings for enhanced keying or bonding to castable linings.

Key Benefits

- Prevents slump, cracking, and blistering in refractory and concrete linings

- Resists corrosion, shock, vibration, and abrasion

- Distributes heavy loads evenly to extend surface life

- Performs reliably in high-temperature and high-impact environments

- Available in multiple metals, heights, and clinch configurations

Downloadable Resources

Overview

Charts

Bearing Bars & Maximum Panel Widths

Load Tables

Standard-Duty Welded - Carbon Steel & Galvanized Steel

Standard-Duty Welded - Stainless Steel

Heavy-Duty Welded - Carbon Steel & Galvanized Steel

Swage-Locked - Aluminum

- GAL & GAL-2 Series | 19-S-4 & 19-S-2 (1-3/16" on Center) Spacing | Rectangular Bar

- SGAL & SGAL-2 Series | 15-S-4 & 15-S-2 (15/16" on Center) Spacing | Rectangular Bar

- GIA & GIA-2 Series | 19-SI-4 & 19-SI-2 (1-3/16" on Center) Spacing | I-Bar

- SGIA & SGIA-2 Series | 15-SI-4 & 15-SI-2 (15/16" on Center) Spacing | I-Bar

- SFT & SFT-2 Series | 19-SF-4 & 19-SF-2 (1-3/16" on Center) Spacing | Rectangular Bar

- TB-626 - SAFE-T-GRID® Series | 19-S-4 (1-3/16" on Center) Spacing | T-Bar

- TB-940 - SAFE-T-GRID® Series | ADA | 19-S-4 (1-3/16" on Center) Spacing | T-Bar

Press-Locked - Aluminum

- GAA & GBB Series | 19-P-4 & 19-P-2 (1-3/16" on Center) Spacing | Rectangular Bar

- GCC & GDD Series | 15-P-4 & 15-P-2 (15/16" on Center) Spacing | Rectangular Bar

- GCM-1 - CLOSE MESH Series | ADA (3/16" Thick Bar) | 7-P-4 & 7-P-2 (7/16" on Center) Spacing | Rectangular Bar

- GCM-4 - CLOSE MESH Series | ADA (3/16" Thick Bar) | 11-P-4 & 11-P-2 (11/16" on Center) Spacing | Rectangular Bar

Press-Locked - Carbon Steel & Galvanized Steel

- GAA & GBB Series | 19-P-4 & 19-P-2 (1-3/16" on Center) Spacing | Rectangular Bar

- GCC & GDD Series | 15-P-4 & 15-P-2 (15/16" on Center) Spacing | Rectangular Bar

- GCM-1 - CLOSE MESH Series | ADA (3/16" Thick Bar) | 7-P-4 & 7-P-2 (7/16" on Center) Spacing | Rectangular Bar

- GCM-4 - CLOSE MESH Series | ADA (3/16" Thick Bar) | 11-P-4 & 11-P-2 (11/16" on Center) Spacing | Rectangular Bar