McNICHOLS® Expanded Metal Resources

Made by slitting and stretching metal sheets to create diamond-shaped openings, McNICHOLS® Expanded Metal is a practical and versatile product line that forms screens, window security panels, machine guards, and more. In the decorative version of the product, shelving, signage, and ceiling tiles are among the most popular applications. Expanded Metal is supplied in a Standard (Raised) diamond pattern or a Flattened diamond pattern. Expanded Metal Grating and Catwalk Grating are also part of our wide range of selections available directly from inventory. Numerous gauges, opening sizes, materials, and sheet sizes are options that will surely fit your project requirements!

How to Specify and Order Expanded Metal

The information below is your step-by-step guide for selecting the right McNICHOLS® Expanded Metal product for your project. By considering each specification, you can ensure the correct sheet, grating, or panel is selected for your application.

Application

Expanded Metal serves a wide range of purposes across industrial, architectural, and commercial applications. Common uses include screening, ventilation, security enclosures, machine guards, ramps, catwalks, and more. Each application may require a specific Expanded Metal type, material, or finish. For inspiration and examples, explore our Expanded Metal Product and Application Gallery.

Expanded Type

The type of Expanded Metal impacts strength, weight, and design versatility. McNICHOLS offers a variety of Expanded Metal Types, including:

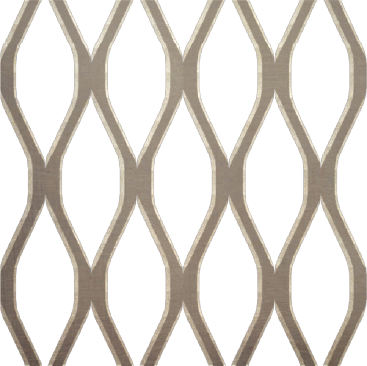

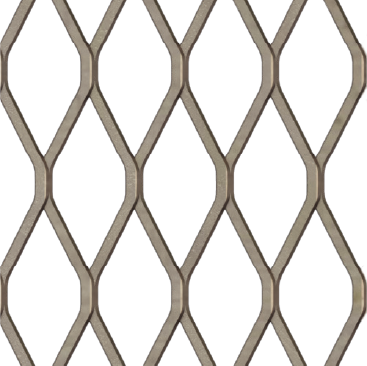

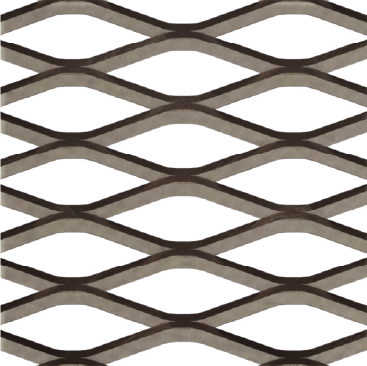

- Flattened Expanded Metal: smooth surface, ideal for aesthetic and architectural projects

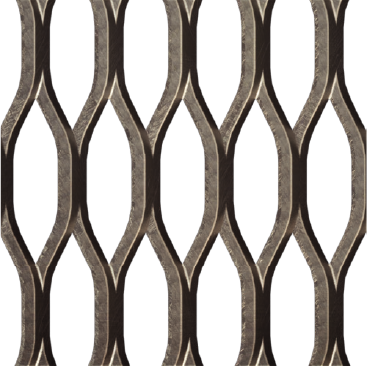

- Standard (Raised) Expanded Metal: provides superior rigidity and traction

- Grating: heavy-duty Expanded Metal for industrial walkways and platforms

- Catwalk Grating: optimized for pedestrian traffic and safety

- Designer Expanded Metal: custom patterns for architectural and decorative designs

Primary Material

The primary material determines strength, corrosion resistance, and suitability for specific environments. McNICHOLS stocks Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel Expanded Metal Sheets and Gratings.

- Aluminum: lightweight and corrosion-resistant, ideal for indoor or outdoor architectural projects

- Carbon Steel: strong and durable for industrial applications

- Galvanized Steel: provides corrosion protection for harsh environments

- Stainless Steel: superior corrosion resistance for demanding applications such as chemical plants or marine settings

See our Primary Material Types for Expanded Metal for more guidance.

Alloy, Grade, or Type

Consider secondary material characteristics, such as specific alloys, grades, or types, that may influence performance. Factors such as temperature tolerance, corrosion resistance, and environmental exposure can be critical in material selection prior to placing your order.

Product Finish

Material finish affects appearance, durability, and corrosion resistance. Most inventory is stocked in mill finish, unless otherwise specified. Additional finishing options, such as galvanizing or powder coating, are available to enhance performance or meet aesthetic requirements.

STYLE & TYPE

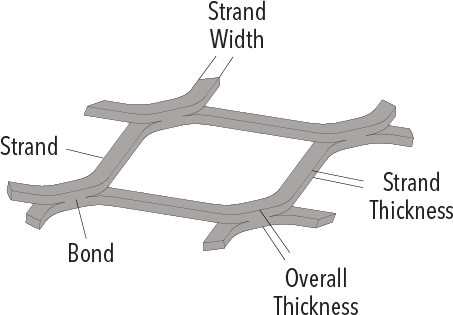

When specifying expanded metal, include:

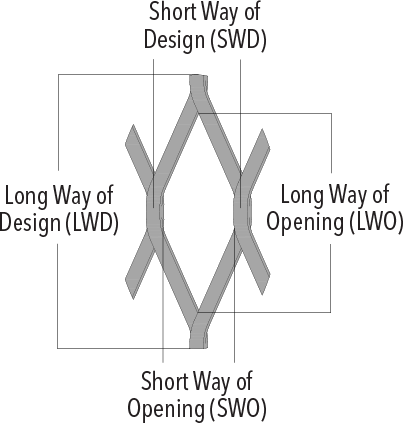

- Short Way of Design (SWD): the measurement of the long strand or diamond length in inches

- Material Gauge or Thickness: determines sheet strength and weight

- Expanded Type: for example, 3/4" No. 9 Flattened

For Grating and Catwalk Grating, specify pounds per square foot (e.g., 3.14# Grating, Standard). This ensures proper load capacity and structural performance for your project.

Percent Open Area

Open area represents the percentage of the sheet that is void versus solid. Open area affects airflow, visibility, weight, and overall performance. Selecting the proper percentage ensures your expanded metal meets functional and aesthetic needs.

Product Size, Form, & Quantity

Specify the number of sheets, desired sizes, and form. McNICHOLS can provide cut-to-size sheets and accommodate shearing preferences such as bond shear or random shear. This ensures your expanded metal is ready for installation or fabrication without additional processing.

Special Requirements

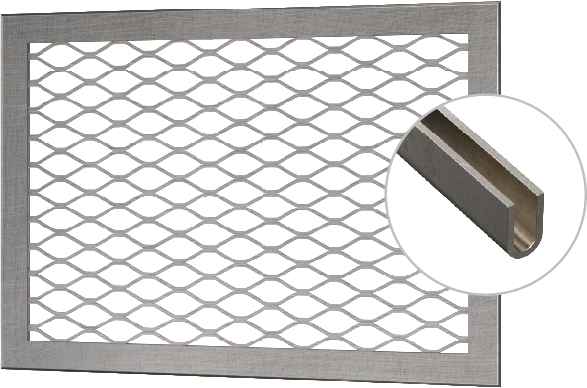

Identify any special project needs such as fabrication, edge treatments, finishing, leveling, or non-standard tolerances. For infill panel projects, use our Infill Panel Worksheet to guide your specifications.

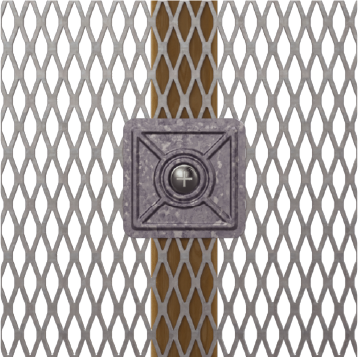

Accessories

Complete your installation with Expanded Metal Accessories, including Clips, U-Edging, and Fasteners. These components provide framing, structural integrity, and finishing touches to secure and support your projects.

Charts & Tables

Fraction Conversion Chart

The Fraction Conversion Chart provides quick reference conversions between fractions, decimals, and millimeters to assist with specifying and comparing Expanded Metal.

Walkways Application Guide

This Walkway Application Guide helps determine the appropriate Expanded Metal Grating and Catwalk Grating for walkways, ramps, and platforms. It includes information on load capacity, spacing, and safety considerations to ensure structural integrity and compliance with building requirements.

Expanded Metal Tolerances

The Expanded Metals Tolerances Table details standard tolerances for shearing Expanded Metal Sheets, helping designers and fabricators account for manufacturing variations and maintain precise installation standards.

Infill Panel Worksheet

Use this Infill Panel Worksheet to determine the open area, weight, and other key details when designing with Expanded Metal Infill Panels. It serves as a planning tool to ensure accuracy in architectural and structural applications.

Learn more about Infill Panels and how they are used in railing systems, facades, and other designs.

Primary Metal Types

Explore the Primary Material Types used in Hole Products, including Carbon Steel, Stainless Steel, Aluminum, and more. Each material offers unique benefits for strength, durability, and appearance.

RAL Color Finishes

Explore available RAL powder coat color options for Expanded Metal. Durable and customizable finishes enhance both protection and aesthetics in architectural and industrial applications.

Grating Load Tables

The Grating and Catwalk Grating Load Table provides load capacities, including weight per square foot and maximum allowable loads. It is an essential tool for structural planning, helping engineers and designers select the correct Expanded Metal for safe and efficient applications.