McNICHOLS® Fiberglass Grating Resources

Fiberglass Grating is a lightweight and sound alternative to Steel or Aluminum Gratings. Corrosion-resistant and fire-retardant, the product line is ideal for outdoor use or in corrosive environments. McNICHOLS carries Molded and Pultruded construction types in a variety of sizes, resins, and colors. Most Fiberglass Grating has a slip-resistant, gritted surface to help prevent slips and falls. McNICHOLS also carries Fiberglass Grating Stair Treads. For information on Fiberglass Grating Stair Treads, please visit our Stair Tread Resources landing page.

Benefits of Fiberglass Grating

- Chemical and corrosion resistance

- Concave or grit surface options

- Easy fabricated or cut-to-size

- Fire retardancy

- Lightweight

- Load-bearing capabilities

- Low electrical conductivity

- Various spacing and grid configurations

- Strength and safety properties

- Various bearing bar heights and grid heights

- Various resins and colors

- ADA-compatible choices in both Molded and Pultruded construction types

How to Specify & Order Fiberglass Grating

The information below will guide you in selecting the right McNICHOLS® Fiberglass Grating product for your project. Please review each category to ensure your order meets your application requirements.

Application

Determine the intended use and physical requirements of your Fiberglass Grating. Consider exposure to chemicals, extreme temperatures, and fire-retardant needs. Evaluate loading, span, and support requirements.

Several McNICHOLS® Fiberglass Grating products comply with the Americans with Disabilities Act (ADA) when installed to published standards. Browse Fiberglass Grating applications in our Product and Application Gallery for inspiration and use-case examples.

Construction Type & Shape

Choose the appropriate construction type based on performance and design needs:

- Molded Grating: Available in square or rectangular grid patterns.

- Pultruded Grating: Available in I-Bar, T-Bar, or Wide T-Bar profiles.

Series Type & Name

Select the series that best fits your project (e.g., MS-S-150, MS-I-6010, DURAGRID®).

If your project requires ADA compliance, verify that the product description includes this designation.

Resin Type

Select the resin formulation that meets your application’s environmental and performance needs. Common resin types include FFR Polyester, SFF Polyester, SGF Polyester, SPF Polyester, SPH Phenolic, SVF Vinyl Ester, and XVE Vinyl Ester.

Each resin type offers varying levels of corrosion resistance, UV protection, and fire retardancy.

Color

Choose a Fiberglass Grating color that aligns with your design or operational requirements. Common options include Green, Yellow, and Gray, among others. Color selection can also support safety visibility and design aesthetics.

Grid Height, Size, & Shape (Molded)

For Molded Grating, specify the grid height, surface grid pattern (measured in inches on center), and grid shape (square or rectangular). These factors determine overall strength, open area, and drainage capabilities.

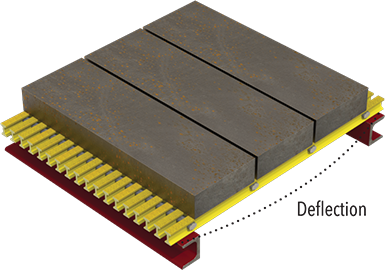

Bearing Bar Size & Shape (Pultruded)

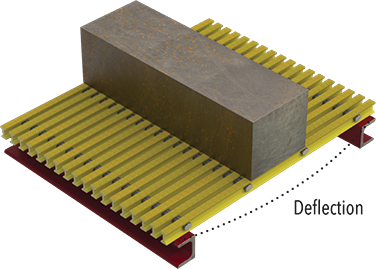

For Pultruded Fiberglass Grating, specify the bearing bar height, top flange width (measured in inches), and bearing bar shape (I-Bar, T-Bar, or Wide T-Bar). These elements directly affect load performance and deflection.

Bearing Bar Spacing

Determine the desired bearing bar spacing, measured from center to center. Spacing impacts load capacity, open area, and weight.

Bearing Bar direction

The bearing bar direction should be parallel to the span (length) to support the load. Clear span, the distance between supports, is curcial for installation. Load Tables offer values for Uniform Load ("U") and Concentrated Load ("C") to assess load types. Consider weight distribution and deflection--whether stationary, evenly distributed, or pedestrian traffic--since each impacts performance and longevity. For installation or application concerns, consult an engineer for safety.

Product Surface

Identify the surface type suited for your environment and safety requirements:

- Concave Surface (Molded Only): Smooth, easy-to-clean finish.

- Grit Surface (Pultruded): Available in fine, medium, or coarse grit for enhanced slip resistance and traction.

Percent Open Area

Select the percentage of open area that provides the right balance of strength, airflow, and drainage for your application.

Span

Specify the bearing bar direction, which determines the span and load distribution.

For Pultruded Grating, span direction refers to the bearing bar orientation. For rectangular Molded Grating, span refers to the long direction of the grid pattern.

Product Size, Form, & Quantity

Identify the number of panels and dimensions required, including width and length.

Specify if panels need to be cut to size, notched, or prepared for stair treads. Areas larger than standard panel widths may be supplied in multiple sections.

Special Requirements

List any additional fabrication or performance requirements, including non-standard tolerances, cut-outs, or custom shapes.

Accessories

Determine if Fiberglass Grating Accessories, such as Clips, Fasteners, or Hardware, are needed for your project. These components ensure proper installation and long-term structural integrity.

Specifying & Ordering Fiberglass Grating Stair Treads

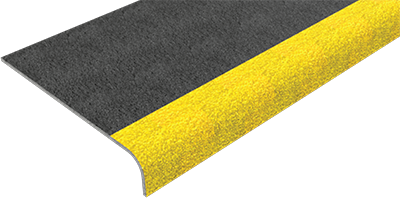

The information below will help you select the right McNICHOLS® Fiberglass Grating Stair Treads for your project. Each option is engineered for strength, corrosion resistance, and slip resistance, ideal for industrial, commercial, and outdoor environments.

Application

Determine the intended use and performance needs of your Fiberglass Grating Stair Treads. Consider factors such as exposure to chemicals, moisture, or extreme temperatures. Identify fire-retardant requirements as well as load capacity and support conditions.

For design inspiration and project examples, explore Fiberglass Stair Tread applications in our Product and Application Gallery.

Construction Type

Choose from several construction options to best meet your application--All types can be cut to size for installation-ready performance.

Series Type & Name

Identify the series type and name of your selection (e.g., MS-STC-09, MS-I-ST-6015, DURAGRID®). Series designations help ensure the proper profile, strength rating, and compatibility with your project specifications.

Resin Type

Select the appropriate resin system to achieve the best chemical resistance, temperature tolerance, and durability for your environment. Common resin options include SPF Polyester and other performance-based formulations.

Color

McNICHOLS offers Fiberglass Stair Treads in several color options, such as Green, Yellow, and Gray, to enhance visibility or match design preferences. Molded and Pultruded Stair Tread types are both available in multiple finishes for safety and aesthetic integration.

Grid Height, Size, & Shape (Molded)

For Molded Stair Tread Panels, specify the grid height, grid pattern (in inches on center), and grid shape (rectangular with integral nosing on both panel lengths).

Molded Stair Tread Cover Panels feature a 3/16"-thick solid surface with an integral 90° angle nosing for easy installation over existing steps.

Bearing Bar Size & Shape (Pultruded)

For Pultruded Stair Tread Panels, determine the bearing bar height, top flange width, and bar shape (standard I-Bar design). Each Pultruded panel includes a 2"-wide integral nosing along one side for improved traction and visibility.

Product Surface

Select the surface texture that best suits your safety and maintenance needs:

- Molded Stair Tread Cover Panels and Molded Stair Tread Panels are supplied with a durable grit surface.

- Pultruded Stair Tread Panels feature a medium grit surface for balanced slip resistance and cleanability.

Nosing

McNICHOLS® Fiberglass Stair Treads feature integral nosing designed for durability and visibility:

- Molded Stair Tread Cover Panels: Yellow 90° nosing extends 2" across the front edge and surface for safety.

- Rectangular Molded Panels: Include a 1-5/8" wide nosing on both lengths.

- Square Molded Panels: Feature a 1-3/4" wide nosing on both sides.

- Pultruded Panels: Include a 2" wide nosing with medium grit for enhanced traction.

Percent Open Area

Select the percentage of open area desired for your application. Molded Stair Tread Covers feature a solid surface with no open area, while Molded and Pultruded panels include openings for drainage and weight reduction.

Product Size & Quantity

Specify the number of Stair Treads and their dimensions (width and length).

- Width is measured from the front edge of the nosing to the back edge of the tread.

- Length (span) is measured from the outer edges of the panel or bearing bars.

Note: Molded and Pultruded Stair Tread widths are sometimes referred to as depth.

Special Requirements

Identify any custom fabrication, notching, cutouts, or non-standard tolerances needed to meet your project’s installation or safety standards.

Accessories

Explore our related Accessories to find hardware and components designed for fast, secure Fiberglass Grating installation.

Clips & Fasteners

Fiberglass Grating, both Molded and Pultruded, is normally held in place with clips or fasteners. There are several types available, some for holding adjacent panels together and others for fastening a panel of Grating to a structural member.

These are several options to consider:

Embed Angles

Embed Angles are essential for Fiberglass Grating applications. Providing necessary support and stability, Embed Angels frame and anchor panels and ensure precise alignment and load-bearing capacity.

Explore our Embed Angles resource page to learn more about the different types, installation tips, and guidelines for your Fiberglass Grating projects.

Value-Added Services

Our Value-Added Services overview highlights McNICHOLS' capabilities, such as cutting, fabrication, finishing, and custom packaging for Fiberglass Grating.

Below are details on available cut-to-size options.

Cut-to-Size Options for Molded Fiberglass Grating:

Closed Cell: Cut-to-size pieces with no partial grid members sticking out. "Closed cell" is only accomplished when the dimensions required match the dimensions of a closed cell cut precisely.

Open Cell: Cut-to-size pieces with partial grid members sticking out.

Cut-to-Size Options for Pultruded Fiberglass Grating:

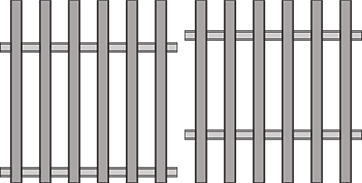

Random Stubs: The most cost-effective and standard cut. When two equally sized, randomly cut pieces are placed side-by-side, the cross-rods may not line up. The measurements for equal pieces are the same, but distances from the bearing bar ends (stubs) to the cross-rods vary from piece to piece and end to end.

Uniform Stubs: Two equally sized, uniformly cut pieces are placed side-by-side, and the cross-rods line up but may not be centered. The measurements for equal pieces are the same, but the distance from the bearing bar ends (stubs) to the crossbars will not be the same on both ends. It will, however, be uniform from piece to piece.

Equal Stubs: When two equally sized pieces with equal cut stubs are placed side-by-side, the cross-rods will line up and be centered. The measurements for equal pieces are the same, and the distance from the bearing bar ends (stubs) to the cross-rods will too.

Construction Types

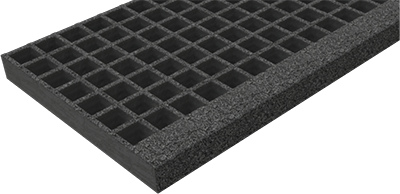

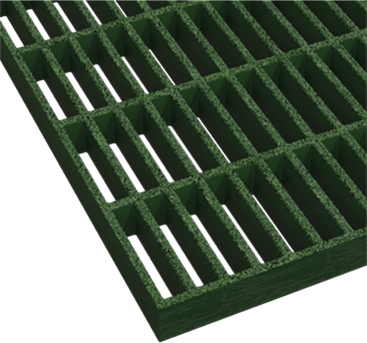

Molded

McNICHOLS® Molded Fiberglass Grating is the product of choice where corrosion resistance or fire retardancy is paramount and high impact resistance is important. When compared to steel, this product is very lightweight. Molded Fiberglass Grating is composed of fiberglass rovings combined with a choice of resin systems.

The one-piece construction panels offer a comfortable, concave, or slip-resistant walking surface and can be easily cut to size in the field. Molded offers great versatility because of its one-piece construction and will often eliminate the need for additional support for cut edges. With its characteristic grid pattern, the Grating is able to bear loads in any direction without the need for continuous side supports.

Shapes include Square and Rectangular Grid and come in a variety of sizes, resins, and colors.

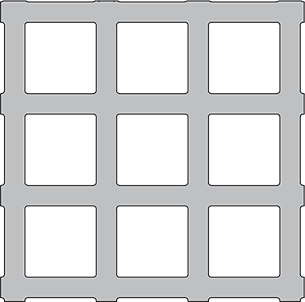

Square Grid (Molded)

Square Grid (MS-S) Molded Fiberglass Grating is an economical product of choice when corrosion resistance, fire retardancy, and high-impact resistance are paramount. When compared with steel, this product is very lightweight but still retains the ability to support heavy loads. Square Molded comes in several heights and grid pattern sizes.

McNICHOLS also carries an ADA-Compliant product (M-M-150) with a 3/4" x 3/4" square grid pattern on the top surface of the Grating with the bottom grid pattern being 1-1/2" x 1-1/2" square. This unique design consolidates the strength of a typical 1-1/2" x 1-1/2" square grid item and reduces the open area necessary to comply with ADA code requirements.

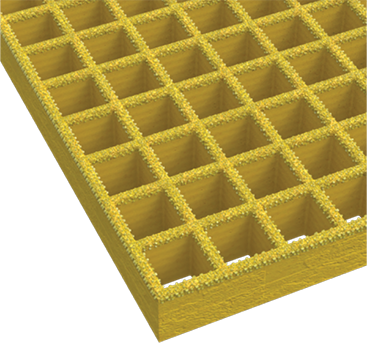

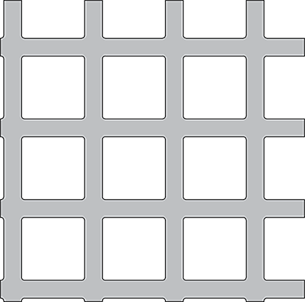

Rectangular Grid (Molded)

Rectangular Grid (MS-R) Molded Fiberglass Grating panels are also corrosion-resistant and fire-retardant. The most common rectangular grid size is a 1" height with a 1" x 4" grid. We also supply a 1-1/2" height with a 1-1/2" x 6" grid pattern. Typical color selections are green and dark gray. Panels can be supplied with a concave or slip-resistant grit surface. Like Square Molded, Rectangular Molded is made with resin and glass rovings that combine to form the rigid Grating panel.

In addition to stocking several sizes of Rectangular Molded Fiberglass Grating, McNICHOLS also carries a Rectangular Molded Stair Tread Panel that has integral nosing on both sides equal to the long dimension of the product. The surface has a grit applied to it for slip resistance. These panels can be purchased in full stock lengths or cut down to the size you require!

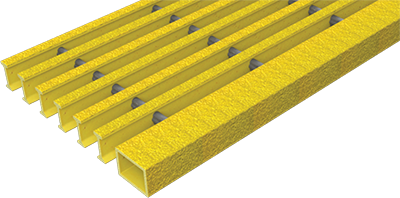

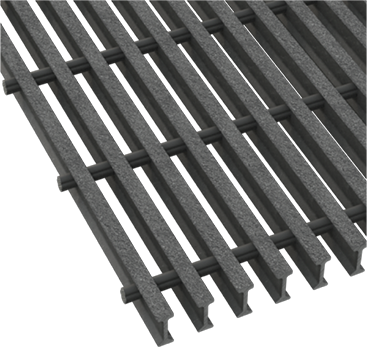

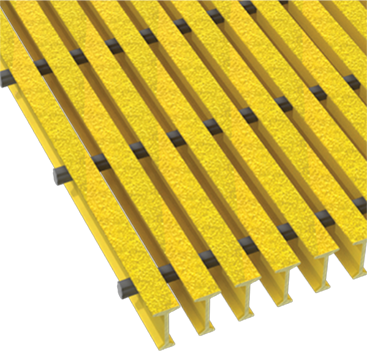

Pultruded

McNICHOLS® Pultruded Fiberglass Grating is a composite of fiberglass reinforcements (fibers and mat) and a thermosetting resin system, formed by the pultrusion manufacturing process. Pultruded Grating bearing bars use both longitudinal (glass roving) and multidirectional (glass mat) reinforcements and a synthetic surfacing veil to provide unequaled strength and corrosion resistance.

The densely packed core of continuous glass rovings gives the bar strength and stiffness in the longitudinal direction (span), while the continuous glass mat provides strength in the transverse direction and prevents chipping, cracking, or lineal fracturing. Since glass is the key contributor for the structural performance, Pultruded Grating offers the highest strength-to-unit weight ratio among construction types.

Pultruded Grating is a desirable option for structural applications that require minimum deflection under high loads because of its incredible strength and stiffness. It is available in I-Bar, T-Bar, and Wide T-Bar pultrusions in several different panel sizes.

Pultruded I-Bar

Our Fiberglass Pultruded I-Bar Grating has I-shaped bearing bars with perpendicular cross-rods placed every 6". McNICHOLS refers to this Grating as DURAGRID® in the MS-I-4000 and MS-I-6000 series. We also carry an I-Bar product with an 8" cross-rod spacing known as MS-I-6515 – DURADEK®.

Downloadable Resources

Charts

The Charts section brings together technical data for Fiberglass Grating, including load capacities, tolerances, and material comparisons. Reference these tables for quick, accurate information when designing or specifying your project.

Fiberglass Grating Chemical Resistance Guide

To match resin systems to specific chemical exposures, use our Fiberglass Grating Chemical Resistance Guide. This essential tool ensures you select materials that perform reliably in harsh or corrosive environments.

Fraction Equivalent Chart

Our Fraction Equivalent Chart converts measurements between fractional, decimal, and metric units. It’s a convenient reference for engineers and fabricators working across multiple measurement systems.

Fiberglass Grating Tolerances

The Fiberglass Grating Tolerances Chart details allowable variations in panel dimensions and bearing bar placement. Use this guide to confirm that your grating meets McNICHOLS quality standards and project specifications.

Primary Material Types

To see the available material types for Fiberglass Grating, explore our Primary Material Types Chart and find the best solution for your application.

Resin | Type | Description

The Resin Characteristics Chart explains available resin options for Fiberglass Grating, including Polyester, Vinyl Ester, and Phenolic types. Use this resource to identify the ideal resin system for your environmental and structural needs.

Load Tables

Square Molded

Rectangular Molded

Pultruded I-Bar

- MS-I-4010 - DURAGRID® | ADA | 1.000" Bearing Bar Height | I-Bar

- MS-I-4015 - DURAGRID® | ADA | 1.500" Bearing Bar Height | I-Bar

- MS-I-6010 - DURAGRID® | 1.000" Bearing Bar Height | I-Bar

- MS-I-6015 - DURAGRID® | 1.500" Bearing Bar Height | I-Bar

- MS-I-6515 - DURADEK® | 1.500" Bearing Bar Height | I-Bar

Pultruded T-Bar

- MS-T-3310 - DURAGRID® | ADA | 1.000" Bearing Bar Height | T-Bar

- MS-T-3320 - DURAGRID® | ADA | 2.000" Bearing Bar Height | T-Bar

- MS-T-5010 - DURAGRID® | 1.000" Bearing Bar Height | T-Bar

- MS-T-5015 - DURAGRID® | 1.500" Bearing Bar Height | T-Bar

- MS-T-5020 - DURAGRID® | 2.000" Bearing Bar Height | T-Bar