McNICHOLS® Perforated Metal Resources

McNICHOLS carries the largest inventory of Perforated Metal products in North America, with a vast selection of sizes, gauges, materials, and hole types available. In both high-end and industrial settings, Perforated Metal brings strength and style to enclosures, partitions, sign panels, guards, screens, and other structures. The material offers ventilation, versatility, and a high strength-to-weight ratio. Perforated Metal is also an excellent product for filtration (sound, liquid, light, etc.) applications.

Overview

Perforated Metal is manufactured by punching or laser-cutting regular patterns of holes into sheet metal. Available in a wide range of materials—Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel—Perforated Metal combines functional performance with aesthetic value.

This page centralizes technical charts, specification guidance, and product decision tools to help you choose the right perforated solution.

How to Specify and Order Perforated Metal

The information below is your step-by-step guide for selecting the right McNICHOLS® Perforated Metal product for your project. Considering each specification carefully will help ensure you get the correct sheet, plate, or panel for your application.

Application

Perforated Metal can serve a wide variety of purposes across industries. Common applications include displays, exhibits, fixtures, partitions, cabinet inserts, guards, furniture, building facades, infill panels, and more. Each use may require different material properties, hole types, or finishes. For inspiration and real-world examples, explore our Perforated Metal Applications in the Product and Application Gallery.

Hole Type

The hole type is one of the most important factors to specify, as it defines both functionality and appearance. McNICHOLS offers a wide variety of Perforated Hole Types, including:

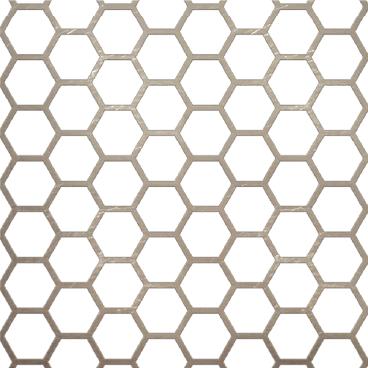

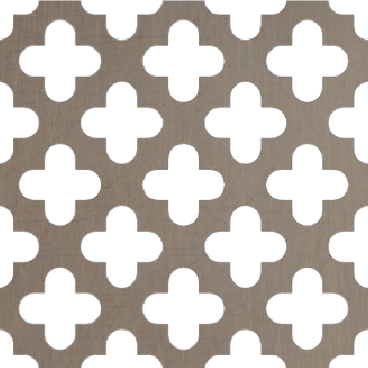

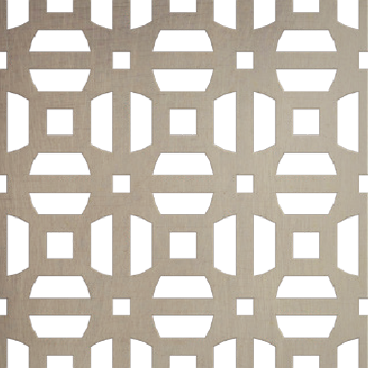

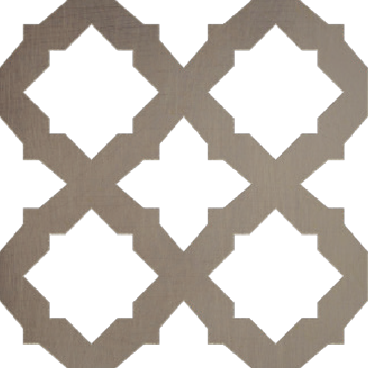

Designer Perforated Metal

Combines versatility and elegance, offering a high-end look with functional benefits. Various patterns available.

Primary Material/Product Finish

The choice of material and finish impacts durability, weight, and overall performance. McNICHOLS stocks Aluminum, Carbon Steel, Galvanized Steel, Stainless Steel, and Plastic Perforated Metal Sheets.

Most items are stocked in mill finish unless otherwise specified. Additional Finishes such as anodizing, powder coating, or galvanizing, are available to enhance corrosion resistance or aesthetic appeal.

Alloy, Grade, or Type

For projects requiring specific material characteristics, consider the alloy, grade, or type. Factors such as temperature resistance, corrosion resistance, and environmental exposure should guide your selection. For example, stainless steel grades differ in performance for food processing, marine, or industrial environments.

Gauge/Thickness

Material thickness determines strength, weight, and workability. Specify the required gauge or thickness in inches. For guidance, see our Gauges, Thicknesses, and Weights by Primary Material reference chart. This tool helps compare sheet thicknesses across Aluminum, Carbon Steel, and Stainless Steel.

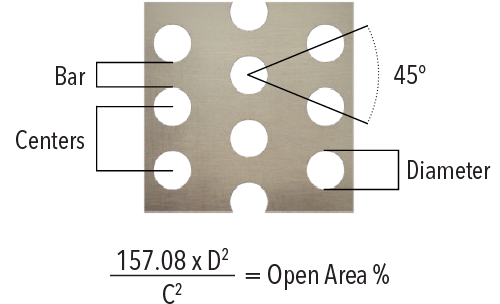

Hole Pattern

Hole pattern defines how the perforations are arranged on the sheet. Specify the following:

- Hole Size (Diameter or Dimension)

- Hole Type (Shape)

- Hole Center (Spacing between holes)

- Hole Arrangement (Staggered centers, straight centers, or reverse staggered centers)

Or, for architectural needs, the Designer Perforated series name and number.

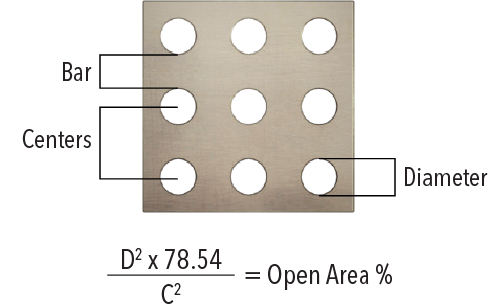

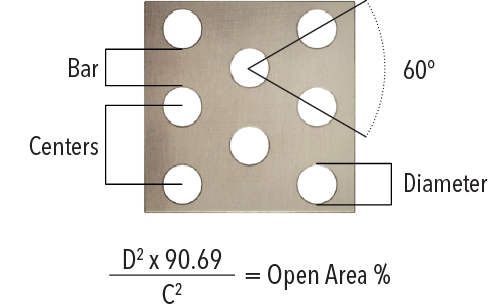

Percent Open Area

Open area represents the percentage of perforated surface versus solid metal. It affects airflow, light transmission, weight, and visibility. Use our Open Area Reference Table to determine the right balance for your project.

Margins/End Pattern

Margins refer to the solid (unperforated) border along the edges of a sheet. Consider the following when specifying:

- 11 Gauge and lighter sheets typically have minimum solid side margins and no end margins.

- Heavier sheets (above 11 Gauge) may include finished or unfinished patterns with corresponding end margins.

Margins affect both fabrication requirements and installation appearance.

Product Size, Form, & Quantity

Specify your required sheet or plate size, form, and quantity. Standard perforated sheets are typically supplied flat, but McNICHOLS can also provide cut-to-size pieces. Materials 3/16" thick or greater are classified as plate. Identifying your desired dimensions upfront helps ensure faster processing and accurate quoting.

Special Requirements

If your project requires customization beyond standard stock, note any special cut-to-size requests, margin adjustments, edge treatments, finishing, leveling, fabrication, or non-standard tolerances. For infill panel projects, refer to our downloadable Infill Panel Worksheet to guide your specifications.

Accessories

Complete your installation with Perforated Metal Accessories. These components provide framing, edge protection, and finishing touches to enhance both functionality and appearance.

Charts & Tables

Fraction Conversion Chart

The Fraction Conversion Chart provides quick reference conversions between fractions, decimals, and millimeters to assist with specifying and comparing Perforated Metal hole sizes and dimensions.

Infill Panel Worksheet

Use this Infill Panel Worksheet to determine the open area, weight, and other key details when designing with Perforated Metal Infill Panels. It serves as a planning tool to ensure accuracy in architectural and structural applications.

Learn more about Infill Panels and how they are used in railing systems, facades, and other designs.

Perforated Metal Flatness Tolerances Chart

The Flatness Tolerance Chart outlines industry standards for flatness tolerances in Perforated Metal sheets, helping ensure product quality and consistency during fabrication and installation.

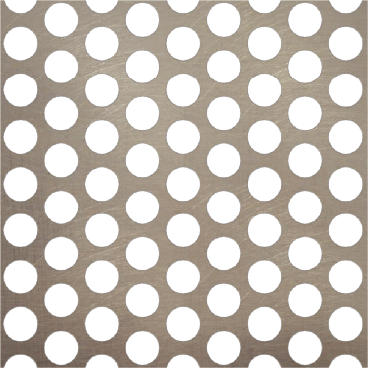

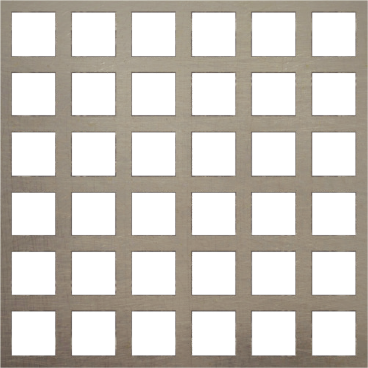

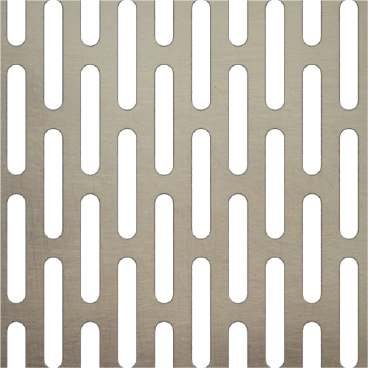

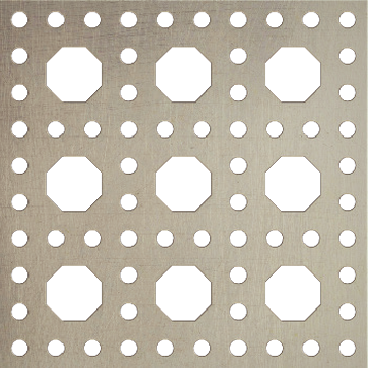

Perforated Metal Hole Types to Scale

View common Perforated Metal Hole Types to Scale, including round, square, slotted, and decorative options. This reference aids in visualizing design possibilities.

Perforated Metal Shearing Tolerances

The Shearing Tolerances Table details standard tolerances for shearing Perforated Metal Sheets, helping designers and fabricators account for dimensional variations during cutting and processing.

Primary Material Types

Explore the Primary Material Types used in Hole Products, including Carbon Steel, Stainless Steel, Aluminum, and more. Each material offers unique benefits for strength, durability, and appearance.

RAL Color Finishes

Explore available RAL powder coat color options for Perforated Metal. Durable and customizable finishes enhance both protection and aesthetics in architectural and industrial applications.

Gauges, Thicknesses, & Weights by Primary Material

The Gauges, Thicknesses, and Weights Table lists common gauges, thicknesses, and corresponding weights for Perforated Metal across primary material types. It provides a reference for selecting the appropriate sheet strength and weight for your application.

Round Hole & Square Hole Percentages of Open Area

The Open Area Table illustrates the percentage of open area for round and square hole patterns in Perforated Metal. Open area impacts airflow, light passage, and weight, making this a key factor in design and performance considerations.

Materials & Finishes

Primary Material Types Overview

- Aluminum: Lightweight, corrosion-resistant, and excellent for facades and interior decorative applications. Good for anodizing or powder coating.

- Carbon Steel: Economical and strong; often used where structural stiffness is required. Best with galvanized or painted finishes for corrosion protection.

- Galvanized Steel: Carbon steel with zinc coating for outdoor corrosion protection; ideal for industrial and exterior use.

- Stainless Steel: Best corrosion resistance (304, 316); used in marine, food, medical, and architectural applications.

- Plastic/Composite: Lightweight and corrosion-proof for niche filter/screening uses.

Finishing Options and When to Use Them

- Mill Finish: stock, neutral appearance.

- Hot-dip Galvanizing: best for long outdoor life in corrosive environments.

- Powder Coat: wide color range with improved corrosion protection; recommended for architectural projects.

- Anodize: Aluminum only—durable, metallic finish; good for UV and abrasion resistance.

- Passivation/Electropolishing: stainless steel options to optimize corrosion performance and hygiene.

Design Considerations: Performance & Aesthetics

Acoustics, Light, & Ventilation

Perforated Metal is widely used in acoustic panels (with backing absorbers), light diffusers, and ventilation grilles. Sound-absorption performance is a function of open area, hole diameter, and backing material depth.

Structural & Load Considerations

For walkable infill, stair panels, or areas carrying load, consult Gauges & Load tables and consider backing reinforcement, framing, or composite panels to meet deflection limits.

Maintenance & Lifecycle

Material choice and finish determine maintenance needs. Galvanized or stainless options extend service life in corrosive settings; powder coat extends aesthetics but requires careful touch-up processes for scratches.