McNICHOLS® Wire Mesh Resources

Wire Mesh (also referred to as Wire Cloth) has the strength to perform in industrial settings, the aesthetics to enhance architectural designs, and the versatility to fulfill a variety of functions. Routinely incorporated into signs, railing infills, cabinet inserts, plant screens, and other applications, this dynamic product family suits nearly any design. Its lightweight properties make it easy to cut to size and handle during installation. McNICHOLS carries an extensive selection of mesh and opening sizes, wire diameters, patterns, and materials.

How to Specify and Order Wire Mesh

The steps below will help guide you on how to specify McNICHOLS® Wire Mesh for your project. By considering each factor, you can ensure that your Wire Mesh meets both functional requirements and design expectations.

Application

Wire Mesh is versatile and used across many industries. Common applications include screens, partitions, architectural facades (such as parking garages and building exteriors), cabinet inserts, and enclosures. Each use may require a different mesh opening size, construction type, or finish. For real-world examples, explore our Wire Mesh Application Gallery.

Mesh Type

Select from a wide range of mesh styles to achieve the desired look and performance:

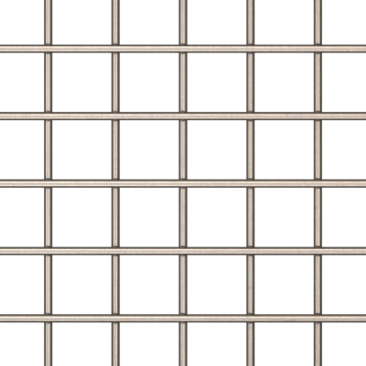

- Square Wire Mesh: uniform openings suitable for many industrial and architectural uses

- Rectangular Wire Mesh: elongated openings for directional strength or airflow

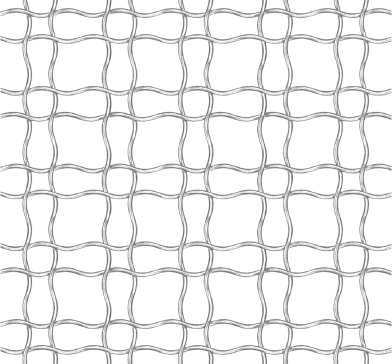

- Designer Mesh: decorative patterns tailored for architectural & specialty applications

Construction Type

Wire Mesh is manufactured in two main ways:

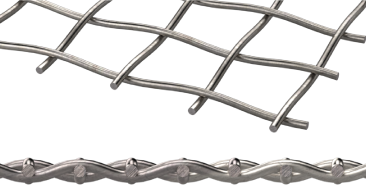

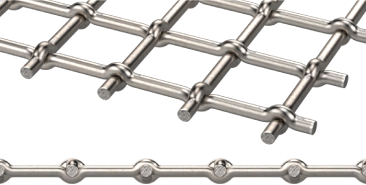

Woven Wire Mesh

Created by weaving wires over and under in alternating patterns, producing a flexible, visually appealing structure. Common weave styles include Plain Weave, Lock Crimp, and Intercrimp, among others.

Welded Wire Mesh

Primary Material & Finish

Material choice determines the durability, appearance, and suitability for your environment. McNICHOLS® Wire Mesh is available in several different material types to meet our customers’ specific project needs. The most common inventoried materials are:

- Plain Steel (Carbon)

- Aluminum

- Pre-Galvanized Steel

- Hot-Dipped Galvanized

- Brass

- Bronze

- Copper

- PVC Coated

- Stainless Steel 304

- Stainless Steel 316

Most items are supplied in mill finish unless otherwise specified. Some items are available with vinyl coatings for added protection. Additional finishes such as powder coating can be applied for enhanced corrosion resistance or color options.

Alloy, grade or type

Certain projects may require specific alloys, grades, or types to meet performance needs. Factors like temperature tolerance, corrosion resistance, and environmental conditions should be considered before selecting your Wire Mesh product.

Weave, Trim, or Series Name & Number

Depending on construction, specify the appropriate detail:

- Woven Wire Mesh: Select the weave style (e.g., Plain Weave, Lock Crimp, or Intercrimp).

- Welded Wire Mesh: Indicate whether the mesh is trimmed or untrimmed.

- Designer Mesh: Identify the series name and number (e.g., TECHNA™ 3155).

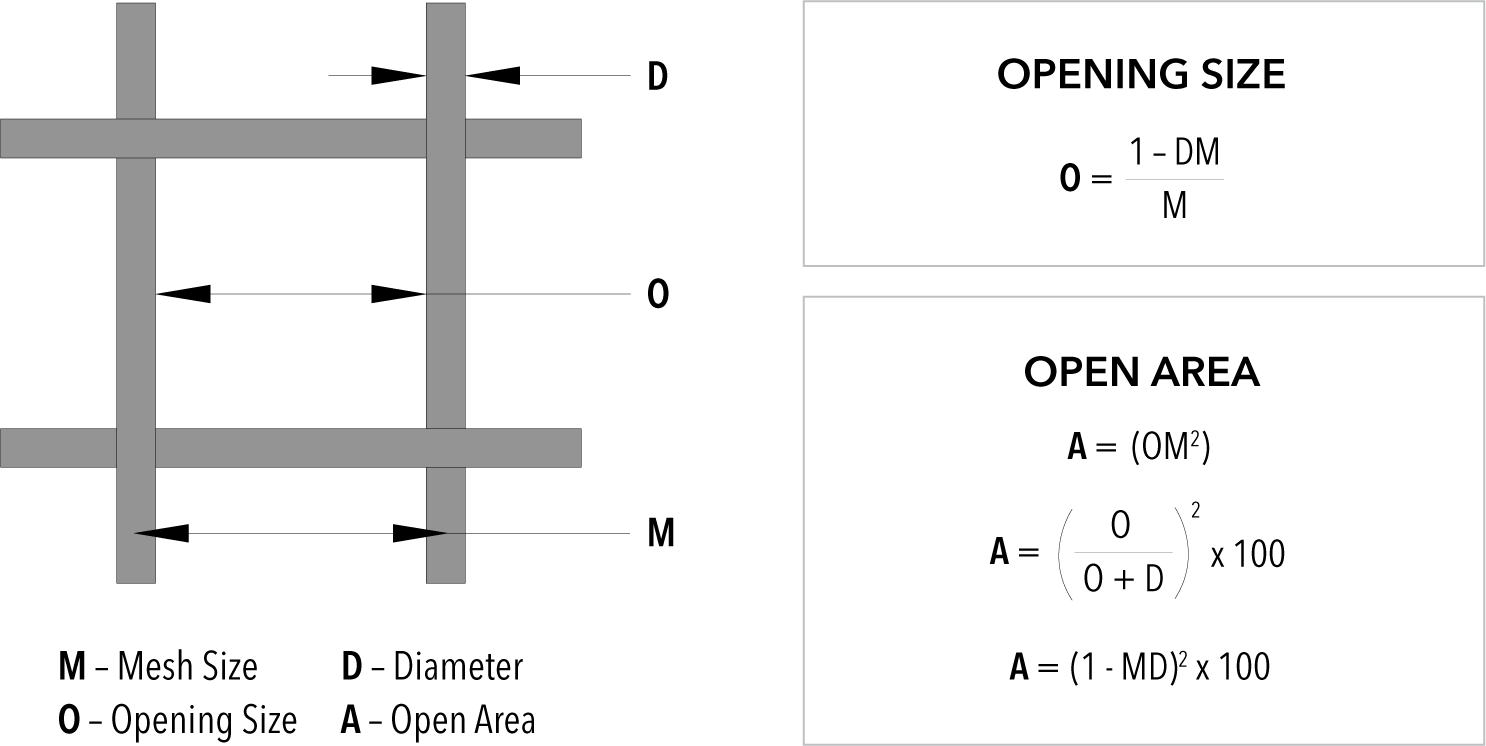

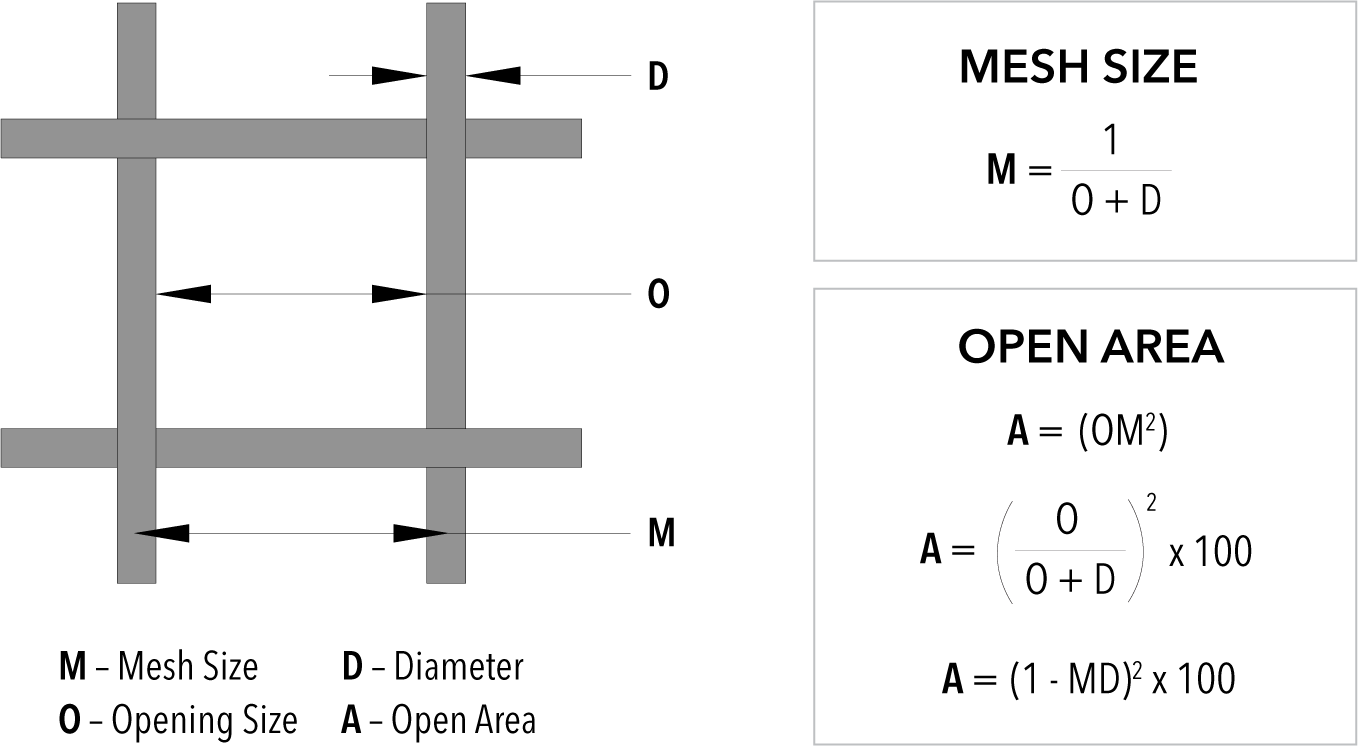

Opening Size

Define the clear opening of the mesh, measured from the inside edge of one wire to the inside edge of the next. For rectangular mesh, both width and length measurements are required. Opening size directly impacts airflow, visibility, and filtering capability.

Mesh Size

In addition to opening size, many Wire Mesh items are classified by mesh size. This refers to the number of openings per linear inch or the center-to-center measurement of adjacent wires.

Fine meshes are ideal for filtration and screening, while larger meshes provide open visibility and airflow. McNICHOLS stocks a wide range of mesh sizes to accommodate both functional and decorative needs.

Specifications for the measurement of mesh openings are further highlighted below. Note that the higher the number (i.e., specified amount of openings per 1"), the smaller the opening sizes for mesh.

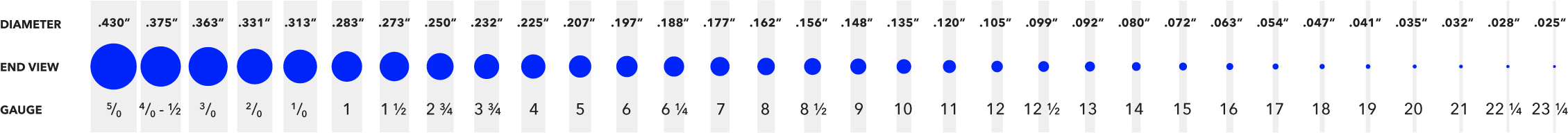

Wire Diameter/Wire Gauge

Specify the wire thickness in either inches or by gauge number. See our Wire Diameter and Gauge Conversion Chart for reference. Wire diameter impacts strength, weight, and percent open area.

Percent Open Area

Percent open area refers to the portion of the mesh surface that is open versus solid wire. This measurement affects airflow, light passage, weight, and appearance—all key considerations in Wire Mesh applications.

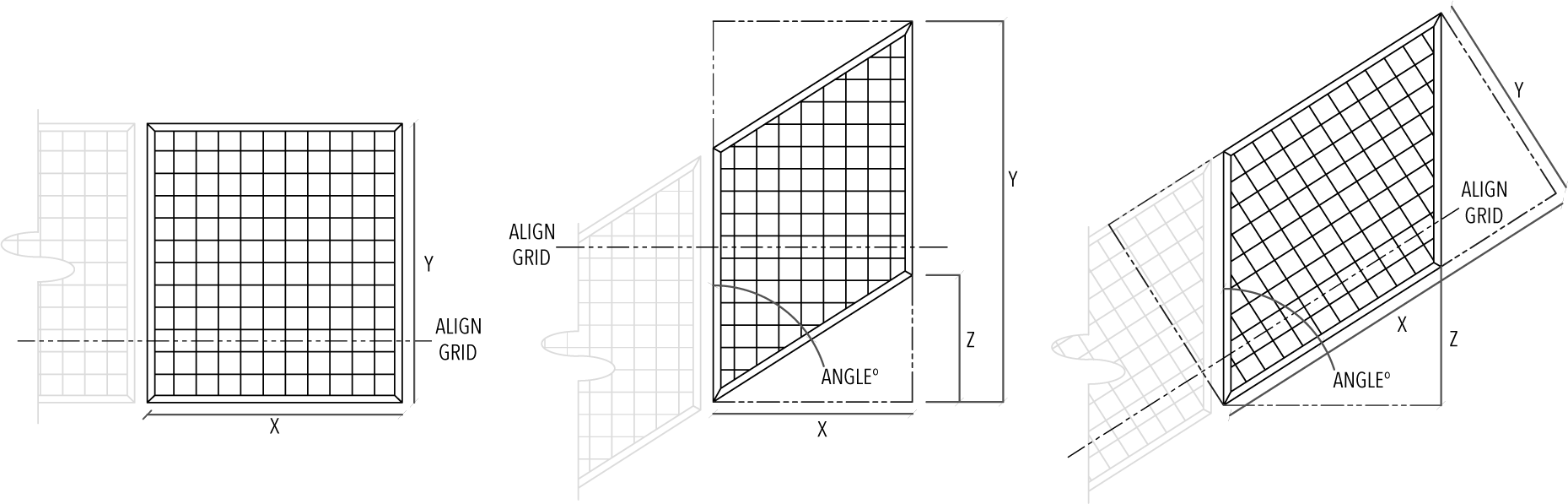

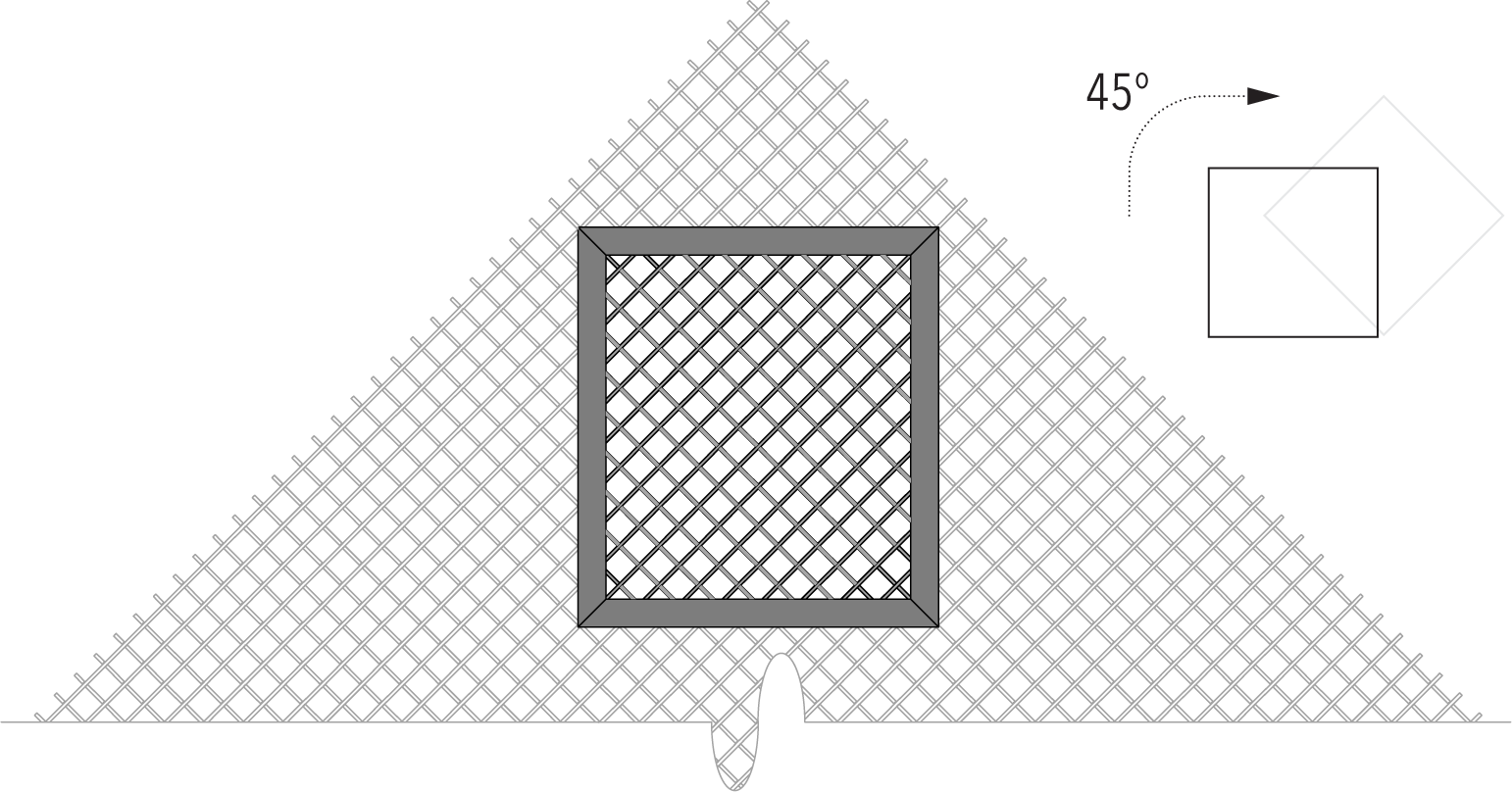

Pattern Orientation

Determine the pattern orientation of the product (parallel to supports, parallel to slope, and/or parallel to horizon). Include dimensions (with framing) and degree of angle for each piece. Indicate if the panels will be installed side-by-side so the pattern can align. Aligning the pattern of adjacent skew panels often requires structural details or shop drawings supplied by the customer.

Product Size, Form, & Quantity

Special Requirements

Identify whether you need sheets or coils, as well as any cut-to-size requirements. For coils, note any stub preferences, which include trimmed, untrimmed balanced stubs, and untrimmed. Providing these details upfront ensures faster processing and accuracy in your order.

Wire Mesh is available in several different forms:

- Coil: Some items, particularly fine mesh items, are available as a coil, typically 36" or 48" wide by 100 feet in length. Other widths and lengths may be available by special order. Coil stock is sold either as a full coil or by the linear foot. Please submit a quote with the quantities and sizes required for partial coils.

- Sheet: Many Wire Mesh items, particularly large opening and heavy gauge wire items, are available as a sheet. Common sheet sizes are 3' x 8', 3' x 10', 4' x 8', 4' x 10', 5' x 10', and 6' x 10'. If the sheet size required is not in stock, it can usually be made quickly as a special order. Sheet stock is sold in square feet.

- Cut-to-size: McNICHOLS® Wire Mesh can be cut to size from either sheet or coil. Please submit a quote with the details of your requirements.

Some projects require customization beyond standard stock. Please specify any needs such as fabrication, edge treatments, specialized finishing, or non-standard tolerances. For projects involving Infill Panels, refer to our downloadable Infill Panel Worksheet to guide your order.

Accessories

Complement your selection with Wire Mesh Accessories such as U-Edging. These accessories provide framing, support, and finishing touches that improve both function and aesthetics.

Benefits of Wire Mesh

Woven Wire Mesh:

- Flexible, easy to shape

- Variety of opening sizes

- Available as rolls, sheets, panels, or cut-to-size

- Available in small openings

Welded Wire Mesh:

- Solid construction

- Easy handling

- Wires resist movement

- Flush edge trim available

Designer Mesh:

- Aesthetic appeal

- Versatile

- Architecturally inspired

- Variety of openings and sizes

- Unique design and appearance

- Style and functionality

- Strength

ECO-MESH®:

- Creates privacy screens with natural elements

- Absorbs carbon oxides, metal particles, and emissions

- Protects from UV, weather, and temperature fluctuations

- Buffers wind and sound

- Strong and durable while being lightweight

The Types of Wire Mesh

McNICHOLS offers Square and Rectangular styles of Wire Mesh, and a range of Designer patterns. We also offer the modular façade and trellis systems called ECO-MESH®.

McNICHOLS® Square Wire Mesh is known for its easy handling and solid construction. Woven and Welded styles both have a variety of internal and external applications, including screens, partitions, and façades for parking garages and other structures. Interior uses include cabinet inserts and partition screens in commercial and residential spaces alike.

- WOVEN

Square Woven Wire Mesh is the most popular mesh McNICHOLS offers. This product features a series of wires that are woven together, resulting in a weave pattern. The most common patterns are Plain Weave, Lock Crimp Weave, and Intercrimp Weave. Woven Mesh is a flexible product, depending on the gauge and weave type.

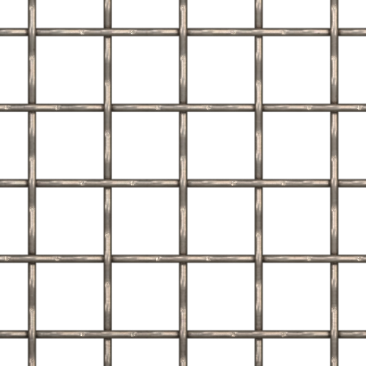

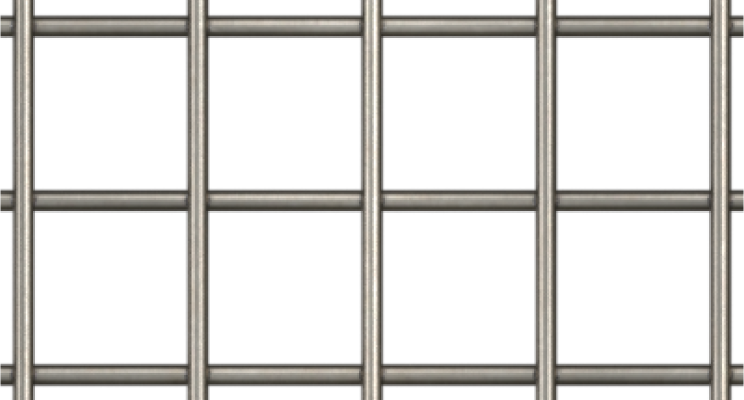

- WELDED

Square Welded Wire Mesh typically has larger openings than Woven Wire Mesh. In this product, wire strands are welded at each intersection, yielding an overall stronger construction, and it is capable of maintaining its shape when stressed.

Rectangular Wire Mesh has many of the same properties as Square Wire Mesh. The primary difference is the rectangular opening that is created when the mesh is constructed. McNICHOLS stocks both Woven (often referred to as Insect Screen) and Welded varieties.

- RECTANGULAR – WOVEN (INSECT SCREEN)

Rectangular Woven Mesh, also referred to as Insect Screen, features a woven wire mesh construction. Small insects, such as no-see-ums, may pass through a typical insect screen (18 x 14 mesh), but smaller meshes from 20 to 325 are available to slow down most bugs.

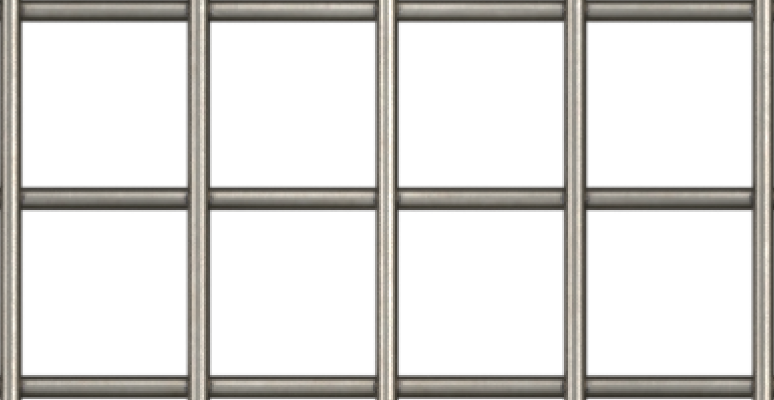

- RECTANGULAR – WELDED

Rectangular Welded Wire Mesh typically has larger openings than Woven Wire Mesh. With the wire strands welded at each intersection, Welded Wire Mesh is more capable of maintaining its shape when stressed. The product is a popular choice for railing infill panels.

Designer Wire Mesh is constructed of wires that are woven into numerous unique architectural patterns.

Applications include ceilings, stairway infill panels, overlay surfaces, wall cladding, sunshades, partitions, store fixtures, cabinet infills, signage or sign backing, aesthetic accents, and more.

Hardware and Industrial Cloth is available in a Welded or Woven construction and widely used in the farming industry due to its corrosion-resistant and lightweight characteristics. The product comes in a hot-dipped, galvanized material.

A vinyl-coated Welded Mire Mesh product, VINYLMESH™ comes in various meshes, gauges, and widths. The product is easy to clean, weather-resistant, and corrosion-resistant. Applications include animal cages, screens, partitions, racking, guards, and others. Available in full 100' rolls only.

ECO-MESH®, a modular façade and trellis system, offers many aesthetic, sustainable, and practical benefits. The panels are strong, durable, lightweight, and well-suited for both interior and exterior spaces. Modular applications include facades, partitions, canopies, arbors, and more. ECO-MESH® panels also promote vegetation growth within the panel grid system.

To specify ECO-MESH®, please indicate the following:

- Application

Wall-mounted or freestanding. ECO-MESH® can be used in a wide range of architectural and green-building applications. Visit our Product and Application Gallery to see ECO-MESH® in action.

- Finish

Mill finish, sandblasted, or eco-friendly powder coating (13 standard colors available)

- Quantity

Please specify the number of panels you will need for your project. Stock panels are available in 48" x 96" dimensions, finished in powder-coated textured black with the standard 2" x 2" mesh and 10 gauge wire.

- Special Requirements

ECO-MESH® panels are available in a variety of custom sizes and shapes. If your project calls for fabrication, unique finishes, or non-standard dimensions, please provide these details when ordering.

- Accessories

A variety of ECO-MESH® Accessories are available, including mounting brackets, posts, and hardware, to ensure proper installation and performance.

Charts, Tables, and Scales

Fraction Conversion Chart

The Fraction Conversion Chart makes it easy to convert between measurement units when specifying Wire Mesh. Use this quick reference to align fractional, decimal, and metric dimensions for more accurate product selection.

Infill Panel Worksheet

Our Infill Panel Worksheet provides a step-by-step guide for ordering Wire Mesh Infill Panels. The worksheet helps ensure accurate measurements and specifications, streamlining the process of incorporating Wire Mesh into railings, partitions, and other framed systems.

Primary Material Types

The Primary Material Types Chart highlights the most common materials used in Wire Mesh, such as Stainless Steel, Aluminum, Carbon Steel, Copper, and Bronze. This chart is designed to help you compare options and select the best material based on strength, durability, and environmental conditions.

RAL Color Finishes

The RAL Color Finishes page shows the range of standard powder coating colors available for Wire Mesh products. This guide allows you to explore popular RAL options and select a finish that complements your project’s design or brand identity.

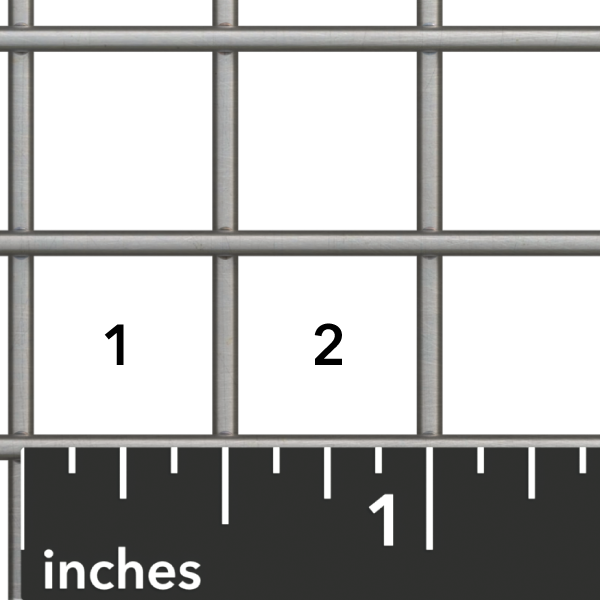

Square Mesh Options | 1 x 1 (1" x 1") Mesh to 90 x 90 Mesh

View our Square Mesh Options (1 x 1 Mesh to 90 x 90 Mesh) Chart for a visual and numerical breakdown of available mesh counts, from coarse 1 x 1 mesh to fine 90 x 90 mesh. Use this chart to quickly compare opening densities and select the right balance of strength and visibility.

Square Mesh Options | 100 x 100 Mesh & Finer

On the Square Mesh Options (100 x 100 Mesh & Finer) Chart, you can views ultra-fine Wire Mesh sizes, starting at 100 x 100 mesh. This resource is especially useful for filtration, separation, or screening applications that require tight openings and high precision.

Square Mesh Sizes to Scale

The Square Mesh Sizes to Scale Chart provides true-to-scale visuals of different mesh counts. By showing actual mesh openings, this chart helps you visualize spacing and select the right size for function and design.

Square Opening Space Screen

The Square Opening Space Screen Chart lists available opening sizes for Wire Mesh, ranging from large 4" x 4" openings to small 1/16" x 1/16" openings. This guide makes it easy to compare clear spaces and choose the correct opening for airflow, light passage, or security needs.

Square Opening Sizes to Scale

Explore our Square Opening Sizes to Scale Chart, which shows actual representations of opening sizes in Wire Mesh. This side-by-side comparison is especially helpful in determining visibility, spacing, and functionality for your specific application.

Wire Diameters & Wire Gauge Equivalents

The Wire Diameters & Wire Gauge Chart connects wire gauge numbers to their corresponding diameters in inches and millimeters. This resource ensures accurate selection of wire thickness and strength when specifying Wire Mesh.

Wire Mesh Tolerances

Lastly, our Wire Mesh Tolerances Chart outlines manufacturing standards for dimensions such as mesh size, opening size, and wire diameter. Understanding these tolerances helps you set proper expectations and ensures your Wire Mesh meets the required specifications.